Capabilities

VIEW OUR PROJECTS

WEMS are specialists in the Wine, Food & Beverage Industry, supplying off the shelf fittings & spares, but also custom design and fabrication of their processing equipment & Structural needs.

Below are some of our projects created for our customers

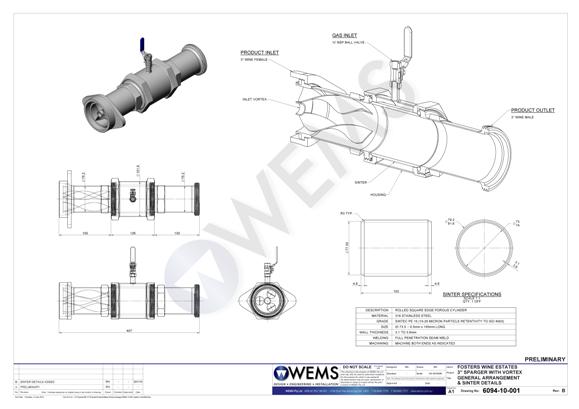

Vortex Sparger

WEMS were approached to help increase sparging efficiency operations at Treasury Estate Wines. We developed a 3” full bore sinter and housing to allow gas sparging to occur from the outside in, which allowed full flow of the product. A vortex fabricated on the sparger inlet increases the mixing of the gas. The result for Wolf Blass is being able to control their DO2 and CO2 levels while pumping at 45,000 - 50,000 L/hr in a single pass. This has greatly reduced the need to rework the product after transferring between tanks.

2" Version also available. All spargers are available with a choice of end connections. Please contact us for further details.

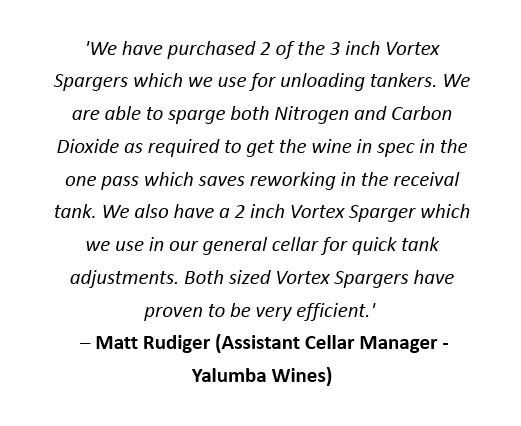

CUSTOMER TESTIMONIALS

'From the initial site inspection, through the design refining on the fantastic computer CAD system, which we found a superb way to convert our winemakers thoughts into engineering actuality, and then watching the on-schedule, pre vintage, instillation go smoothly at an already stressful time, we are very happy to be an ambassador for the WEMS quality approach to customer needs and satisfaction. The added bonus is dealing with a local firm 5 minutes up the road!!'

– Charlie Melton (Winemaker - Charles Melton Wines)

'We are most pleased with the new catwalks installed here [at Penfolds], and we are equally pleased with the seemingly effortless (and more importantly issueless) installation of these catwalks and demolition of the previous installation. This has been a very complex and potentially dangerous job, which WEMS have managed and executed extremely well.'

– Ross Wilkinson (Project Manager - Treasury Wine Estates)

'Whilst knowing that WEMS provided service to the wine industry I asked them if they were able to assist the Light Regional Council with an issue of solids in our waste plant. Through a very accommodating design period they supplied us with a rotating screen which we have installed on our Freeling WWTP it has proven to be very effective in removing solids from the waste stream. Many visitors to the site have commented on how effective the screen is, thanks must go to the team at WEMS!'

– Adam Broadbent (Technical Officer – Wastewater, Light Regional Council)

'If it’s stainless, you guys already stock it! And if not, it is usually supplied in a timely manner. Wine industry product knowledge is exceptional.'

– Adam Diotti (Maintenance Dept - Orlando Wines)

'Very happy with service, items ordered are completed promptly, all items received are of high quality & keep up the good work.'

– Ryan Shepley (Cellar Manager - Richmond Grove)